- Tips & Tricks

- 2 likes

- 11935 views

- 0 comments

Although the concept of an air suspension system on passenger cars was already introduced in the sixties, the functioning of the system is still not common knowledge for most. This is partially the reason that quite some workshops do not have air suspension maintenance and repair as part of their service offer. In this newsletter, Arnott explains the general functioning of the system and components.

System components

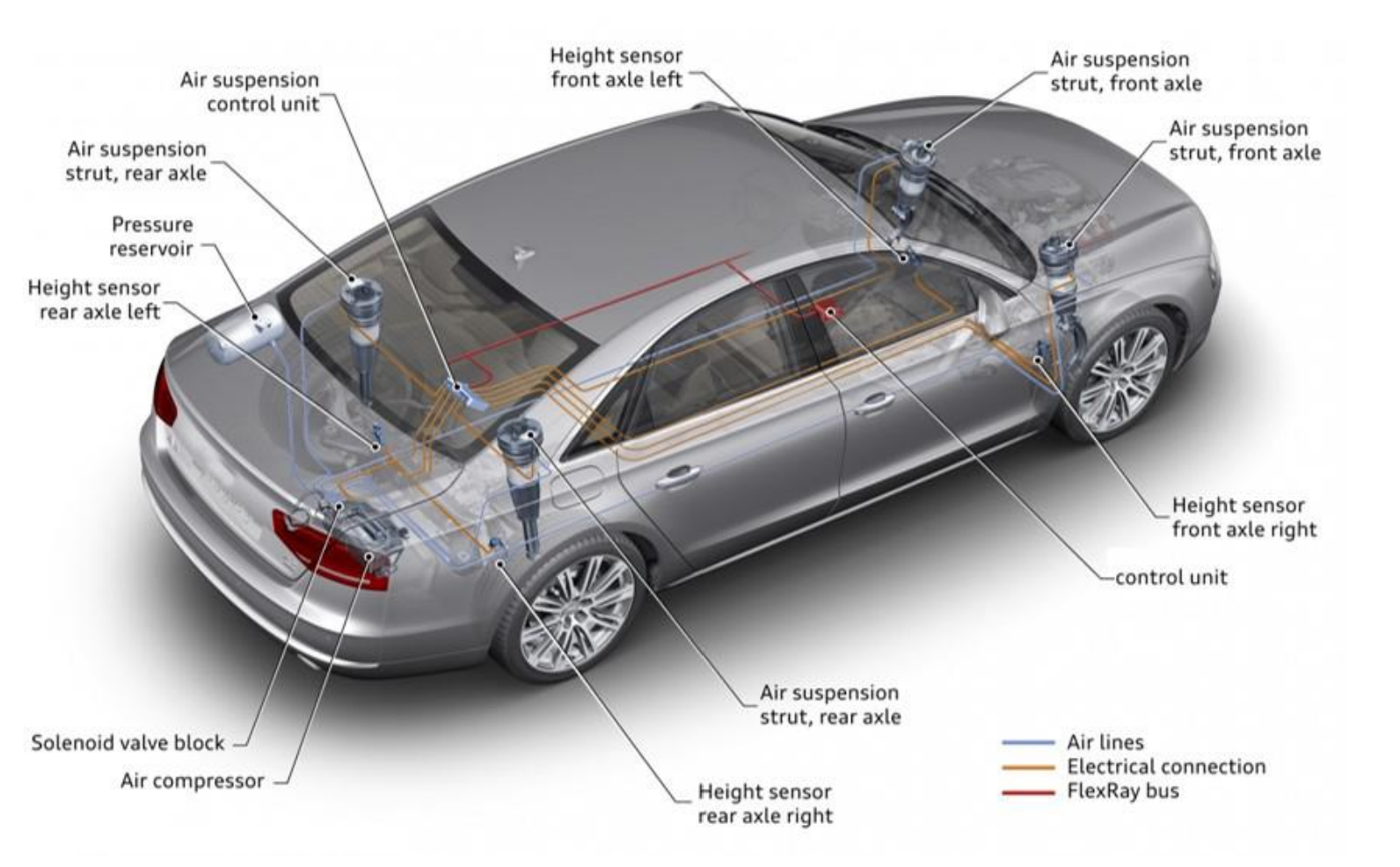

In general,an air suspension system contains the following components:<

• Air suspension struts and/or air springs with separate shock absorbers

• Electronic Control Unit (ECU)

• Air compressor

• Valve block

• Pressure reservoir

• Height sensors

• Air hoses/lines

The suspension struts and shock absorbers of the air suspension system are similar to a conventional suspension system, but the metal coil springs are replaced by air springs. Nevertheless, the air spring does have different characteristics than a coil spring therefore the dampening setting of the shock is tuned differently.

The suspension struts and shock absorbers of the air suspension system are similar to a conventional suspension system, but the metal coil springs are replaced by air springs. Nevertheless, the air spring does have different characteristics than a coil spring therefore the dampening setting of the shock is tuned differently.

The air spring itself is made of durable rubber, with a premium multi-ply cross-corded construction to provide a long-lasting structural integrity. Although air suspension components are wear and tear parts, it can withstand high and low temperatures, and abrasion from dirt and road debris. An airtight construction is provided by stainless steel crimping rings that connect the rubber below with the top and bottom part.

The electronic control unit is the brain of the system. It monitors the system pressure, processes the input signals from the height sensors, controls the valve block and activates the compressor.

The compressor is used for the air supply to inflate the air springs and often contains an integrated dryer as well. Moist is stored in the dryer and evaporates by the heat of the compressor itself.

When the height sensors give a signal to the Electronic Control Unit that the vehicle is not at the predetermined height, the compressor is activated. The air pressure flows through the valve block and air hoses to the air bellow(s). The valve block regulates the direction in which the air pressure flows. Excessive pressure follows the same path back from the air bellow to the valve block.

The pressure is either released (by a pressure-release valve) into the open air or stored in a pressure reservoir. A pressure reservoir contains pressurized air and works like a buffer. It can be used to quickly deliver the required air pressure. This helps regulating the activation of the compressor more efficiently, and it prevents possible overheating caused by constantly switching on and off.

Although the ECU reacts on the signal of the height sensors, it is a common misconception that the system continuously changes the air pressure of the bellows. For example, when the vehicle is cornering, the air springs located on the outside corner do not instantly get more air to keep the vehicle leveled. In this instance, the more advanced systems use electronic shocks that change the damping characteristics in a split second to minimize the body roll.

Although air suspension and conventional suspension systems have similarities, air suspension has some additional benefits like adjustable ride height, improved driving comfort and load leveling capabilities.

---------------------------------------------------------------------------------------------------------------

This information is provided to you by Arnott – Air Suspension Products. With more than 30 years of experience in engineering, designing, and manufacturing high quality air suspension components for the aftermarket, Arnott is the technical expert when it comes to air suspension systems. Arnott’s products are produced with high-quality, OE components offering exact form, fit and function. Each product is extensively tested in our American and European facilities and custom-tuned to suit the specific vehicle make and model before being produced.

Comments (0)